Industrial tree shredders are powerful machines designed to break down wood, branches, and tree trunks into smaller, manageable pieces. Unlike small garden chippers, these heavy-duty machines are built for continuous operation in forestry, recycling, and industrial applications. They transform bulky tree waste into valuable raw materials used in biomass energy, paper production, and landscaping.

An industrial tree shredder is a high-capacity machine that cuts and grinds wood using rotating blades, drums, or discs. The output can range from wood chips to fine mulch, depending on the design and cutting mechanism.

The importance of tree shredders goes beyond waste reduction. They enable:

Sustainable recycling of tree waste into biomass fuels.

Raw material preparation for industries such as pulp, paper, and composite boards.

Efficient land clearing, making construction and agricultural projects more cost-effective.

At the heart of every industrial shredder lies its cutting system. Depending on the design, it can use:

Drum mechanisms → cylindrical drums with sharp cutting teeth.

Disc systems → spinning discs with blades that chip wood.

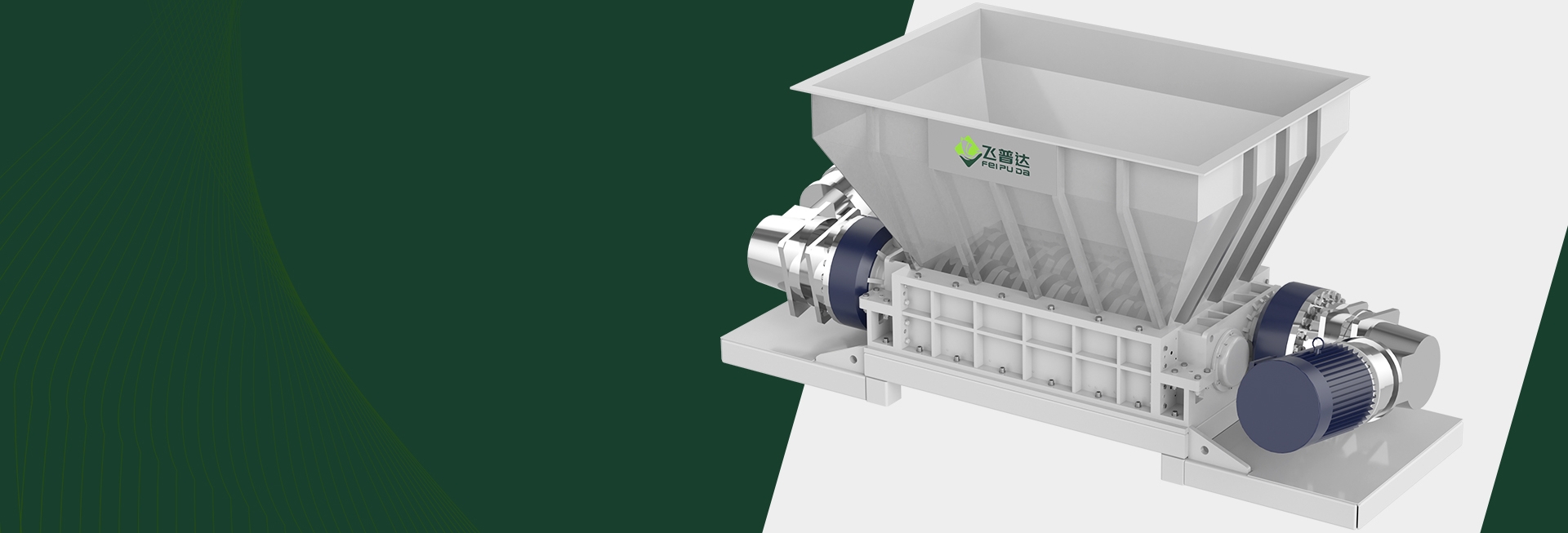

Dual-shaft high-torque systems → counter-rotating shafts designed for extreme loads.

The use of wear-resistant materials like cemented carbide and roll rings enhances durability. Some manufacturers incorporate ribbed roll rings to improve material feed and prevent slippage.

Industrial tree shredders can be powered by:

Diesel engines for mobile units.

Electric motors for stationary shredders.

Hydraulic drives for heavy-duty torque needs.

Power choice affects both energy efficiency and mobility.

Equipped with a rotating drum fitted with cutting teeth, these machines are highly effective for processing large logs and trunks.

Disc shredders use a flywheel-style cutting disc, making them efficient for producing uniform wood chips commonly used in pulp and biomass energy plants.

These machines use two counter-rotating shafts to rip apart even the toughest materials, including wet wood, roots, and mixed waste.

Mobile units are mounted on trailers or trucks, perfect for forestry operations.

Stationary units are installed in recycling plants and factories for continuous operation.

These compact shredders are designed for light-duty tasks, such as clearing small branches, pruning waste, or landscaping materials. They are often portable, with lower power requirements, making them ideal for municipal parks and garden services.

Municipalities and waste management facilities typically use medium-capacity shredders to process tree branches, trunks, and green waste collected from urban and suburban areas. These machines balance efficiency with manageable operational costs, producing wood chips for composting or biomass plants.

Industrial forestry operations and large-scale recycling plants rely on heavy-duty shredders capable of handling logs with diameters exceeding 60 cm (24 inches). These shredders deliver high throughput, sometimes processing several tons of material per hour, making them essential for biomass energy production and large-scale land clearing.

The cutting mechanism is the core of the shredder. Blades, knives, or teeth are often reinforced with cemented carbide to extend their lifespan under high-stress conditions. Advanced shredders also integrate ribbed roll rings to enhance material grip, ensuring consistent feed rates and improved efficiency.

The hopper serves as the entry point for raw material. Some machines use hydraulic-powered rollers to pull in logs, while others rely on gravity-assisted chutes. The design ensures operator safety and steady input control.

Processed wood is discharged via conveyor belts, blowers, or gravity chutes, depending on the machine’s configuration. The discharge system directly affects chip size distribution and the shredder’s compatibility with downstream equipment like biomass boilers or paper pulping systems.

Shredded wood is widely used in biomass power plants to produce renewable energy. Industrial shredders play a key role in converting tree waste into consistent fuel sources for sustainable power generation.

Wood chips generated by shredders serve as the primary raw material for paper, cardboard, and fiberboard manufacturing. Disc shredders are particularly valuable in this industry due to their ability to produce uniform chip sizes.

Tree shredders contribute to waste management by reducing bulky green waste into reusable mulch, compost, and wood chips. This significantly decreases landfill pressure while supporting circular economy models.

In forestry operations, shredders are indispensable for clearing large tracts of land. They are used in construction, agriculture, and road expansion projects, where rapid tree and stump removal is necessary.

By reducing wood into smaller, uniform sizes, shredders improve downstream processing, cutting costs in transportation, handling, and storage.

Industrial shredders promote eco-friendly waste management, transforming tree waste into biomass, mulch, or compost. This reduces environmental impact and contributes to carbon footprint reduction.

Modern shredders are equipped with advanced safety features such as emergency stop systems, feed control mechanisms, and reinforced hoppers. This ensures operator safety while delivering consistent, reliable performance.

The latest shredders integrate programmable logic controllers (PLC), automated feed controls, and remote monitoring systems. This reduces operator dependency while increasing machine productivity.

Innovations in cutting materials have led to the widespread use of carbide-reinforced blades and high-durability roll rings. These upgrades significantly extend tool life, minimize downtime, and ensure consistent shredding performance in harsh industrial environments.

When selecting a shredder, companies should evaluate:

Capacity → throughput per hour.

Material type → softwood, hardwood, or mixed waste.

Power source → diesel, electric, or hydraulic.

Mobility needs → mobile vs. stationary configurations.

While high-performance shredders come with higher upfront costs, their longer lifespan, reduced maintenance, and improved efficiency can lead to better ROI. Businesses should weigh total cost of ownership (TCO) instead of just the purchase price.

Regular inspection and replacement of blades.

Lubrication of moving components.

Monitoring wear on roll rings and feed rollers.

Ensuring proper tension in drive belts and hydraulic systems.

Always use protective gear during operation.

Never feed oversized or inappropriate materials.

Maintain clear emergency stop access.

Provide operator training for handling unexpected jams and malfunctions.

Next-generation shredders are expected to feature AI-driven predictive maintenance and IoT-enabled monitoring systems, allowing operators to track performance in real time.

As industries move towards zero-waste policies, shredders will become more integrated with biomass conversion plants, recycling facilities, and circular economy systems. Eco-friendly innovations, such as low-emission motors and energy recovery systems, will further enhance sustainability.

Q1: What is the difference between a chipper and an industrial shredder?

A chipper produces uniform wood chips, while an industrial shredder is designed for heavier loads and mixed materials, including logs, stumps, and roots.

Q2: Can tree shredders handle wet wood?

Yes, high-torque dual-shaft shredders are designed to process wet, fibrous materials without clogging.

Q3: How long do shredder blades last?

Blade lifespan depends on usage and material processed. With carbide reinforcement and proper maintenance, blades can last significantly longer than standard steel versions.

Q4: Are mobile shredders as effective as stationary ones?

Mobile shredders offer flexibility for on-site forestry and land clearing, while stationary units are ideal for high-capacity, continuous industrial use.

Q5: What industries benefit most from tree shredders?

Forestry, paper and pulp, biomass energy, recycling, landscaping, and construction industries rely heavily on shredders.

Q6: How do roll rings improve shredder performance?

Ribbed roll rings improve grip and material feed consistency, preventing slippage and enhancing overall shredding efficiency.

The industrial tree shredder has become an indispensable machine across industries, from forestry and biomass energy to recycling and pulp manufacturing. Its versatility, efficiency, and sustainability benefits make it a cornerstone of modern industrial waste management and resource recovery.

By selecting the right shredder type, capacity, and configuration—and by maintaining it properly—businesses can maximize productivity while reducing costs and environmental impact. With future innovations in AI, IoT, and green technologies, industrial shredders will only grow more advanced, efficient, and sustainable.

Phone: 0086-13816616775

E-mail: sales@fpdgreen.com

Address: 140 Jinjiabang Street, Tanghui Street, Xiuzhou District, Jiaxing City, Zhejiang, China