Managing industrial waste is one of the biggest challenges of the modern era. With industries producing thousands of tons of waste every day, the need for innovative solutions has never been greater. One technology transforming this field is the industrial waste extruder.

This specialized machine compresses, dehydrates, and processes different forms of waste—reducing volume, improving hygiene, and making disposal or recycling more efficient. For companies seeking cost-effective and sustainable waste solutions, adopting industrial waste extruders is no longer optional but essential.

Industrial facilities, municipalities, and hospitality sectors are struggling to cope with increasing waste volumes. From organic kitchen scraps to plastic packaging and chemical by-products, each type of waste requires proper management.

Key sectors generating high volumes of waste include:

Food processing and hospitality: Organic waste, oils, packaging.

Manufacturing industries: Plastic, rubber, metal, chemicals.

Municipalities: Mixed household and industrial waste.

Healthcare and pharma: Hazardous and biological waste.

Without effective management, these materials contribute to pollution, health risks, and regulatory penalties.

An industrial waste extruder operates through a combination of mechanical and thermal processes:

Shredding & crushing – breaking down bulky waste.

Compaction – compressing material to reduce volume.

Extrusion – pushing waste through a press to remove liquids and generate dry, manageable residue.

This results in smaller, sanitized, and easier-to-handle waste, which can then be transported, recycled, or incinerated more efficiently.

Extruders can reduce waste volume by up to 80%, allowing businesses to save on storage and transportation costs. Municipalities benefit from reduced landfill use, extending the life of existing facilities.

Compared to traditional waste management methods, extruders consume less energy and significantly cut down greenhouse gas emissions.

By removing moisture and compacting waste, extruders minimize foul odors, pest infestations, and workplace hazards. This is particularly critical for food and hospitality sectors.

Governments worldwide enforce strict regulations on industrial waste. Extruders help businesses stay compliant while improving sustainability credentials.

Restaurants, hotels, and food factories generate large amounts of organic and packaging waste. An industrial waste extruder ensures clean disposal, better sanitation, and cost savings.

Extruders handle complex waste streams such as plastics, metals, and chemical residues. This not only improves recycling but also enhances safety standards.

Cities adopting industrial waste extruders can process bulk waste more effectively, reducing landfill dependency and improving urban hygiene.

| Feature | Industrial Waste Extruder | Landfilling | Incineration |

|---|---|---|---|

| Volume Reduction | High | Low | Moderate |

| Environmental Impact | Low | High | High |

| Energy Efficiency | High | Low | Moderate |

| Hygiene | Excellent | Poor | Fair |

| Cost Savings | Significant | Limited | High (due to fuel use) |

Clearly, extruders outperform traditional methods in almost every metric.

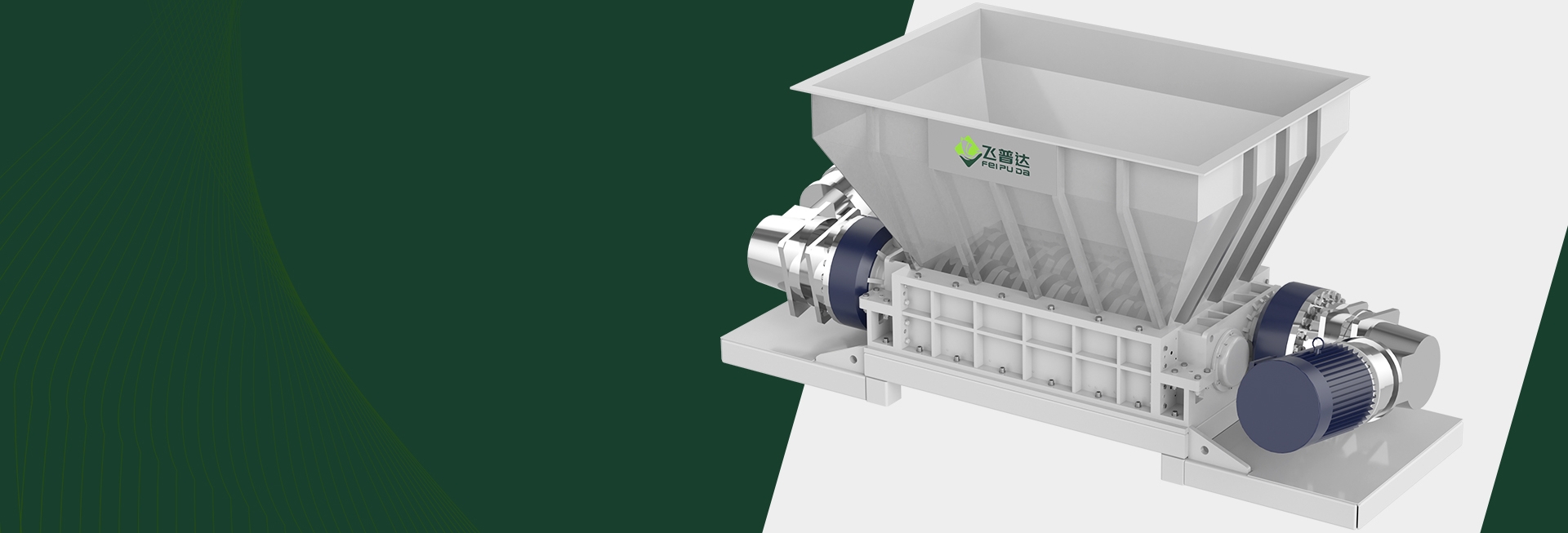

Among the pioneers of waste management technology, FPD Green stands out as a leader in industrial waste extruders. With cutting-edge machinery and an emphasis on eco-friendly design, FPD Green has helped industries, municipalities, and businesses revolutionize their waste handling.

Proven expertise in industrial waste management.

Reliable and durable extruder technology designed for diverse industries.

Cost-efficient solutions delivering measurable ROI.

Commitment to sustainability in line with global green initiatives.

Investing in an industrial waste extruder from FPD Green may require upfront capital, but the long-term savings are undeniable. Companies report:

Up to 50% savings on transportation and disposal costs.

Reduced environmental penalties.

Improved brand reputation as a green business.

The future of industrial waste extruder technology is tied to innovation. We can expect:

AI-powered automation for waste sorting.

Energy recovery systems that convert processed waste into renewable fuel.

Global adoption as sustainability goals become stricter.

Companies like FPD Green will continue leading this evolution, making waste management smarter and greener.

Q1. What types of waste can an industrial waste extruder handle?

It can process organic, plastic, metal, and mixed municipal waste effectively.

Q2. How does it reduce waste volume?

By compressing and extruding waste, volume is reduced by up to 80%.

Q3. Is it suitable for small businesses or only large industries?

FPD Green offers scalable solutions for both small and large operations.

Q4. How does it improve hygiene?

Moisture removal prevents odor, pests, and bacterial growth.

Q5. What makes extruders more sustainable than incineration?

They consume less energy, produce fewer emissions, and facilitate recycling.

Q6. How can FPD Green help my business?

By providing tailored extruder solutions that reduce costs, ensure compliance, and enhance sustainability.

The industrial waste extruder has emerged as a cornerstone of modern waste management. From reducing landfill dependency to cutting costs and enhancing sustainability, its impact is undeniable.

For industries, municipalities, and businesses striving for eco-friendly operations, partnering with a trusted provider is crucial. With its advanced solutions and proven expertise, FPD Green remains a leading choice for organizations worldwide.

Phone: 0086-13816616775

E-mail: sales@fpdgreen.com

Address: 140 Jinjiabang Street, Tanghui Street, Xiuzhou District, Jiaxing City, Zhejiang, China