In industries where material handling efficiency directly impacts costs and sustainability, the shaftless screw conveyor has become an indispensable technology. From wastewater treatment to food processing, these conveyors are designed to handle sticky, wet, fibrous, and irregular bulk materials with ease.

Yet, the performance and reliability of these systems depend heavily on the manufacturer behind the design and construction. Choosing the right shaftless screw conveyors manufacturer ensures not only durability but also long-term efficiency and compliance with industry standards.

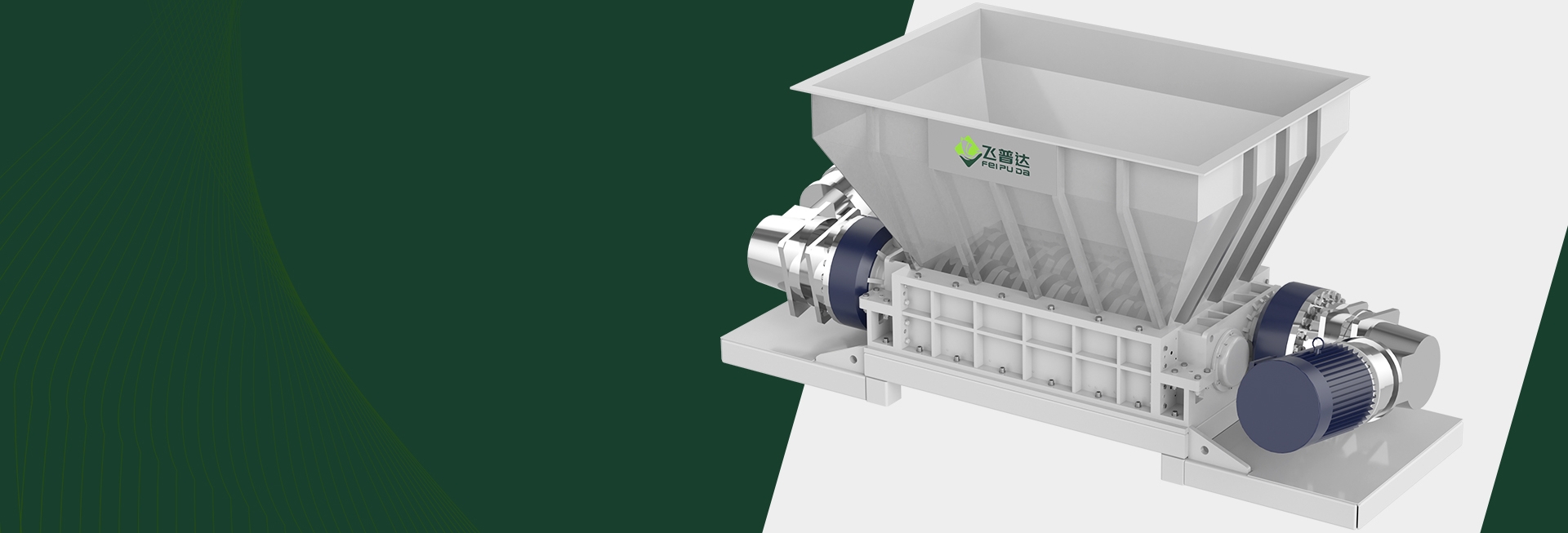

A shaftless screw conveyor consists of a robust helical spiral flighting that rotates inside a lined trough without the need for a central shaft. This open design allows the conveyor to transport challenging materials without the clogs and wear issues common in shafted designs.

Handles sticky, wet, and fibrous materials with less downtime.

Higher fill rates (up to 35% compared to 15% in shafted systems).

Reduced maintenance, as there are no hanger bearings or central shafts.

Extended equipment life thanks to wear-resistant liners and advanced materials.

Widely used in sludge transport, screenings, and grit handling, these conveyors minimize clogging and downtime.

Municipal facilities rely on shaftless conveyors to move organic waste, biomass, and recyclables, ensuring smooth and efficient processing.

Hotels, restaurants, and food production plants use them to handle organic scraps, packaging residues, and wet waste hygienically.

Factories benefit from these conveyors when moving ash, scrap metal, and production byproducts, as they can withstand highly abrasive conditions.

A reputable manufacturer uses hardened steel flights, durable liners, and corrosion-resistant materials, ensuring maximum efficiency and lifespan.

Different industries have unique requirements. The right manufacturer will tailor conveyors for capacity, material type, and installation space.

Reliable manufacturers provide ongoing technical support, spare parts, and maintenance training, ensuring reduced downtime.

Designed to withstand abrasion and wear, spirals are built from high-strength alloys for long-lasting performance.

Manufacturers line troughs with UHMW-PE, steel, or ceramic materials to reduce friction and improve durability.

Advanced manufacturers integrate energy-efficient motors, gear drives, and smart control systems to optimize performance.

Top manufacturers comply with ISO 9001 quality standards, ensuring global recognition of their engineering practices.

Compliance with OSHA, CE, and environmental regulations ensures conveyors are safe and eco-friendly.

Proven industry experience

Use of advanced design and simulation tools

Strong after-sales service

Manufacturers with experience in wastewater, food processing, or recycling are more likely to deliver tailored solutions.

The cheapest option isn’t always the best. Long-term ROI depends on durability, energy efficiency, and reduced maintenance costs.

FPD Green stands out as a leading shaftless screw conveyors manufacturer, offering:

Trusted by waste management, municipal, and manufacturing companies worldwide.

Focuses on energy-efficient conveyors that reduce operating costs while supporting sustainability.

Provides worldwide delivery with localized support, ensuring clients receive reliable service wherever they operate.

Manufacturers are adding sensors and remote monitoring systems to predict wear and optimize performance.

Use of carbide alloys and advanced polymers will further reduce downtime.

Shaftless conveyors are evolving to meet global sustainability goals through low-energy motors and recyclable components.

Q1: What should I look for in a shaftless screw conveyors manufacturer?

Look for experience, certifications, customization options, and after-sales service.

Q2: Are all shaftless screw conveyors the same?

No. Quality, materials, and design vary widely depending on the manufacturer.

Q3: Do shaftless conveyors require frequent maintenance?

They require less maintenance than shafted conveyors but should still be inspected regularly.

Q4: Can shaftless screw conveyors handle abrasive materials?

Yes, when manufactured with wear-resistant flights and liners.

Q5: Is customization available?

Leading manufacturers like FPD Green offer custom-built solutions tailored to industry needs.

Q6: How do I ensure long-term ROI?

Choose a manufacturer that emphasizes quality materials, energy efficiency, and service support.

Selecting the right shaftless screw conveyors manufacturer is a critical decision for businesses in waste management, food processing, recycling, and manufacturing. A well-designed system ensures operational efficiency, reduced downtime, and long-term sustainability.

By partnering with trusted suppliers like FPD Green, businesses gain access to high-quality conveyors, industry expertise, and reliable after-sales support. As the demand for sustainable and efficient material handling grows, choosing the right manufacturer will be key to staying competitive.

Phone: 0086-13816616775

E-mail: sales@fpdgreen.com

Address: 140 Jinjiabang Street, Tanghui Street, Xiuzhou District, Jiaxing City, Zhejiang, China