Efficient material handling is essential for industries dealing with bulk solids, sticky substances, and high-volume waste. Among the various conveying solutions, the shaftless screw conveyor has become a preferred choice for companies looking to move materials reliably, with minimal downtime and reduced maintenance.

This guide explores how shaftless screw conveyors work, their advantages, applications across industries, and why they are vital in modern waste management, food processing, and manufacturing facilities.

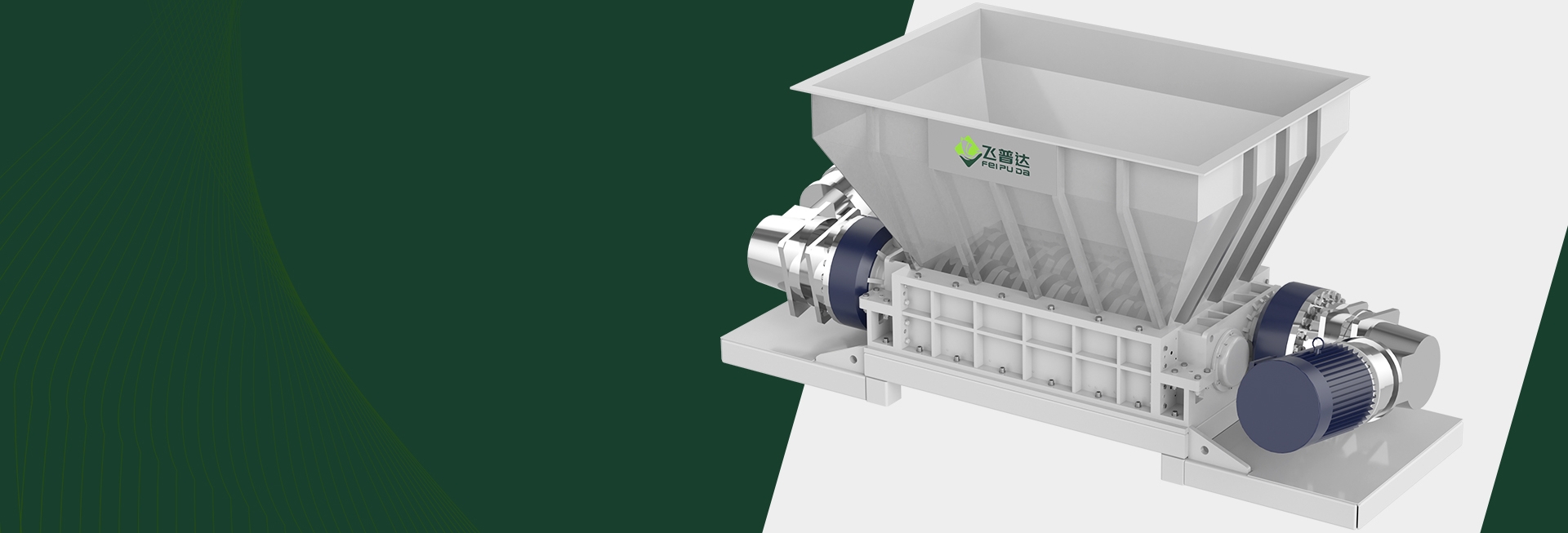

A shaftless screw conveyor is a mechanical transport system that moves bulk materials using a helical spiral (or flighting) without the need for a central shaft. The absence of a shaft allows for greater flexibility, less clogging, and the ability to handle sticky, viscous, or irregularly shaped materials.

Shafted Conveyors → Contain a central shaft with hanger bearings, best for dry, free-flowing materials.

Shaftless Conveyors → Feature a spiral without a shaft, allowing easier handling of wet, sticky, or bulky waste while reducing blockages and wear.

A shaftless screw conveyor typically consists of:

A helical spiral flight made from hardened steel.

A trough or casing with wear-resistant liners.

A drive unit that powers the spiral to move materials along the trough.

As the spiral rotates, it pushes material forward through the trough. Since there is no shaft or hanger bearing, materials with fibrous, sticky, or irregular textures can pass through easily, minimizing downtime due to clogging.

They excel at transporting sludge, food waste, screenings, and other challenging materials that would otherwise clog traditional conveyors.

Shaftless designs allow for higher fill rates (up to 35% vs. 15% for shafted conveyors), improving throughput and efficiency.

With no central shaft or intermediate bearings, there is less wear, fewer blockages, and lower maintenance costs over the machine’s lifetime.

Ideal for moving sludge, grit, and screenings with high moisture content.

Used in waste processing centers to handle organic waste, biomass, and mixed municipal waste.

Efficiently transport food scraps, organic waste, and packaging residues, reducing manual handling.

Crucial in plastics, paper, and organic recycling plants, where wet and sticky materials are common.

Transport metal shavings, ash, and industrial byproducts with minimal clogging and downtime.

The spiral is the most critical part of a shaftless screw conveyor. It is generally manufactured from hardened or wear-resistant steel to handle abrasive materials. The open design provides the flexibility needed to carry sticky, wet, and fibrous waste without clogs.

The spiral rotates inside a trough lined with ultra-high molecular weight polyethylene (UHMW-PE), ceramic, or steel liners. These liners reduce friction, improve efficiency, and extend the equipment’s service life.

A robust gear drive system and motor power the spiral. Depending on the application, conveyors may feature direct-drive or chain-driven units, designed to withstand continuous operation in demanding environments.

Used in food processing plants and municipal facilities, these conveyors handle light to moderate loads while offering compact footprints for easy installation.

Heavy-duty shaftless conveyors can transport hundreds of cubic meters of material per hour, ideal for wastewater treatment, biomass facilities, and manufacturing plants.

Many industries require custom designs tailored to material type, throughput, distance, and layout. Suppliers such as FPD Green offer specialized solutions that integrate seamlessly into existing operations.

Shafted conveyors → Best for dry, free-flowing materials with minimal clogging risk.

Shaftless conveyors → Superior for sticky, wet, or irregular waste streams.

Shaftless conveyors may cost more initially but deliver lower long-term maintenance costs, as they eliminate shaft wear and bearing replacements.

Shafted conveyors → Ideal for powders, grains, and dry bulk.

Shaftless conveyors → Optimal for wastewater sludge, organic waste, and fibrous materials.

Used in organic recycling, composting, and renewable energy plants, supporting sustainable operations.

Municipal waste facilities rely on shaftless conveyors to streamline urban waste processing and reduce landfill dependence.

Factories handling ash, scrap metal, or process byproducts benefit from reliable, clog-free operation.

Perform routine inspections of spiral wear and liner condition.

Clean out troughs regularly to prevent buildup.

Monitor drive units for overheating or unusual noise.

Use wear-resistant liners for abrasive materials.

Lubricate drive components at recommended intervals.

Replace liners before significant wear damages the trough.

Train staff in proper loading techniques.

Always engage emergency stops during blockages.

Use protective gear when working near moving machinery.

Manufacturers are developing spirals made from hardened alloys and composite materials to extend lifespan in abrasive environments.

Automation and sensors allow real-time monitoring of torque, load, and vibration, reducing unplanned downtime.

New models focus on energy-efficient motors, reduced friction liners, and modular designs, aligning with global sustainability goals.

Material properties → wet, sticky, abrasive, or fibrous.

Conveying distance and incline → affects motor power and spiral design.

Capacity requirements → cubic meters per hour to match production needs.

Working with experienced manufacturers such as FPD Green ensures tailored solutions, reliable performance, and long-term support.

Q1: What materials can a shaftless screw conveyor handle?

It can handle sludge, grit, screenings, biomass, food waste, and fibrous materials without clogging.

Q2: How long do the liners last?

With proper maintenance, liners can last years of continuous operation, depending on material abrasiveness.

Q3: Can shaftless conveyors be installed outdoors?

Yes, they can be installed both indoors and outdoors, with protective coatings and covers for weather resistance.

Q4: Are they energy-efficient compared to other conveyors?

Yes, because they achieve higher fill rates and reduced friction, shaftless conveyors are typically more energy-efficient.

Q5: What industries benefit most from shaftless conveyors?

Industries such as wastewater treatment, municipal solid waste, recycling, food processing, and heavy manufacturing gain the most value.

Q6: How do I know if I need a shafted or shaftless conveyor?

If you’re handling dry, free-flowing bulk solids, a shafted conveyor is ideal. For sticky, wet, or irregular waste, shaftless conveyors are the better option.

The shaftless screw conveyor has transformed material handling for industries dealing with wet, sticky, and fibrous waste streams. With its open spiral design, higher fill rates, and reduced maintenance, it offers a cost-effective, durable, and reliable solution for waste management, food processing, and environmental firms.

By choosing the right configuration and working with trusted suppliers like FPD Green, businesses can optimize efficiency, reduce downtime, and support long-term sustainability.

As industries face growing waste management challenges, shaftless screw conveyors will continue to play a critical role in sustainable material handling solutions.

Phone: 0086-13816616775

E-mail: sales@fpdgreen.com

Address: 140 Jinjiabang Street, Tanghui Street, Xiuzhou District, Jiaxing City, Zhejiang, China