In today’s world of rising waste volumes and stricter environmental regulations, the heavy duty industrial shredder machine has become an indispensable tool for industries, municipalities, and recycling facilities. These machines are engineered to handle high-capacity, continuous shredding of diverse waste streams ranging from plastics and metals to organic food waste and municipal solid waste.

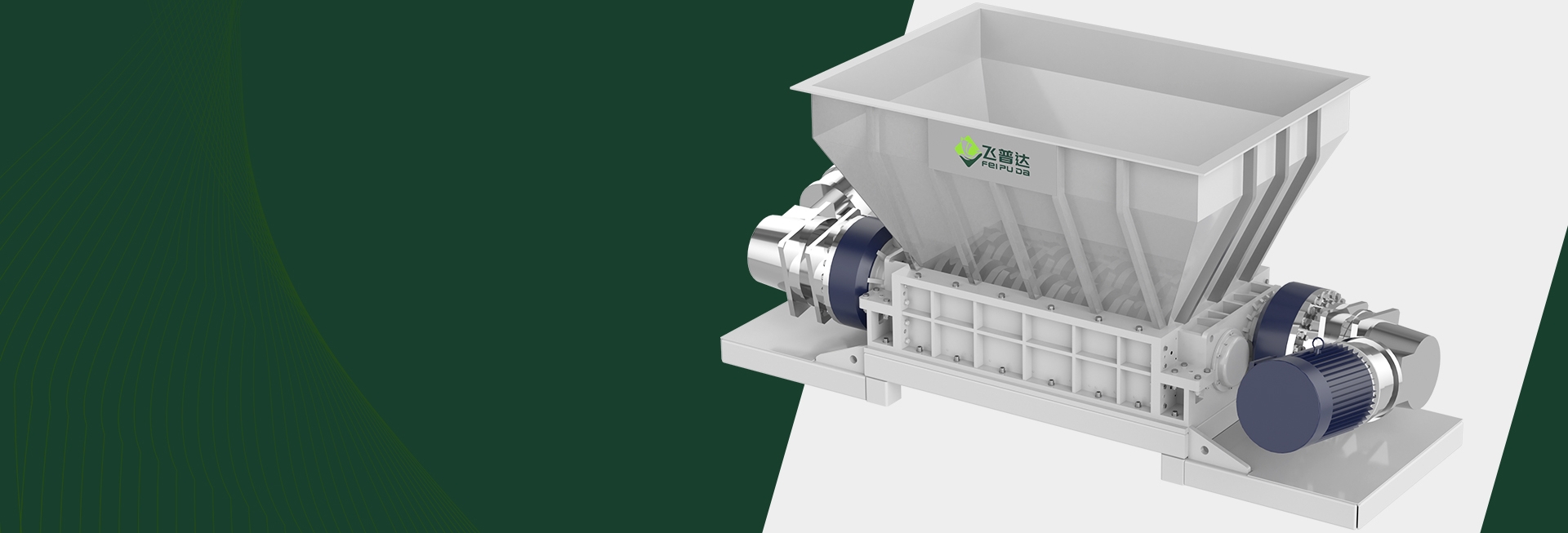

A heavy duty industrial shredder machine is a large-scale waste reduction system designed to cut, tear, or crush solid materials into smaller, manageable sizes. Unlike office shredders, which handle paper, these machines are built with robust cutting systems, high torque, and durable components to process tons of material per hour.

Efficiency in waste reduction → reduces bulk volume for easier handling and disposal.

Resource recovery → enables recycling of plastics, metals, and biomass.

Cost savings → reduces transportation and landfill costs.

Sustainability → supports green initiatives by turning waste into reusable resources.

Industrial shredders rely on rotating shafts equipped with knives, blades, or hooks to tear through materials. Depending on the application, they may feature:

Single-shaft shredding for consistent particle sizes.

Dual-shaft shredding for higher torque and mixed material handling.

Four-shaft shredding for ultra-fine processing and high-security destruction.

These machines require powerful motors, often exceeding 100–1000 horsepower, with torque-driven systems to handle dense and abrasive materials. Hydraulic drives are common in heavy-duty models, providing steady torque output and resistance against jamming.

Ideal for producing uniform output size, commonly used for plastic recycling and biomass applications.

Feature two counter-rotating shafts, designed for high-torque, low-speed shredding of mixed industrial waste.

Combine high-capacity shredding with secondary size reduction, ensuring precise particle sizes for recycling.

Horizontal shredders → suitable for long and bulky items.

Vertical shredders → compact design for smaller spaces and moderate loads.

Municipal solid waste facilities use shredders capable of processing 5–20 tons per hour, making them suitable for urban waste streams.

Large manufacturing and recycling plants utilize shredders that handle 50+ tons per hour, reducing large volumes of plastics, metals, and organic waste.

Some industries require tailored solutions with specialized feeding systems, discharge conveyors, and advanced cutting mechanisms.

Cutting blades are made from hardened steel or carbide, ensuring durability against tough materials. Many shredders now integrate ribbed roll rings, which improve material feeding, prevent slippage, and enhance machine performance.

The hopper ensures safe and controlled feeding of materials into the shredder. Some designs include hydraulic pushers for heavy bulk loads.

Processed waste is discharged via conveyor belts or augers, ensuring smooth transfer to compactors, balers, or recycling lines.

One of the largest applications of heavy-duty shredders is in municipal solid waste management. These machines break down plastics, metals, textiles, and bulky household waste into manageable sizes for sorting, recycling, or incineration. Recycling plants use shredders as the first step in material recovery.

Food processing facilities, hotels, and restaurants generate large volumes of organic waste. Heavy duty shredders convert food scraps, packaging, and even bones into smaller particles that can be composted or used in biogas energy plants, helping businesses reduce landfill use.

Factories and industrial facilities use shredders to handle scrap metal, defective products, packaging, and production waste. By reducing bulk, they lower disposal costs and improve waste recycling efficiency.

Governments and municipalities invest in shredders to manage urban waste streams, green waste, and demolition debris. With proper integration, shredded waste becomes a resource for energy generation or raw material recovery.

By reducing waste size, shredders cut transportation costs, minimize landfill fees, and optimize storage space. They also ensure faster processing in recycling facilities.

Shredders support circular economy models by converting waste into recyclable or reusable resources. From biomass fuels to recycled plastics, they help reduce dependence on virgin materials.

With strict waste disposal laws worldwide, industrial shredders enable companies to meet environmental regulations while avoiding fines and penalties.

Modern shredders are increasingly equipped with carbide-tipped blades that withstand abrasion and high-impact conditions. The integration of ribbed roll rings ensures steady feeding, preventing material jams and enhancing shredding consistency.

Advanced machines now feature:

Programmable logic controllers (PLC) for automatic operation.

Load sensors to adjust feed rates and prevent overload.

Remote monitoring systems for real-time performance tracking.

These innovations improve uptime, reduce labor needs, and extend machine lifespan.

When selecting a shredder, businesses should evaluate:

Material type → plastics, metals, organic waste, or mixed streams.

Processing volume → tons per hour capacity required.

Power source → electric for stationary units, diesel for mobile systems.

Output size → requirements for recycling or downstream processing.

While heavy-duty shredders require a significant investment, their longer operational life, reduced maintenance, and efficiency gains ensure strong ROI. Businesses should consider total lifecycle cost rather than upfront purchase price alone.

Inspect and sharpen blades regularly.

Lubricate moving parts to reduce wear.

Monitor hydraulic systems and motors.

Replace worn-out roll rings and feed rollers.

Train staff on correct feeding practices.

Ensure protective guards and emergency stops are functional.

Use personal protective equipment (PPE) when operating or maintaining the machine.

Never overload the machine with unsuitable materials.

Artificial Intelligence (AI) is being integrated into shredders for predictive maintenance, detecting wear and tear before failures occur. This reduces downtime and boosts reliability.

Future designs will focus on:

Energy-efficient motors to reduce power consumption.

Hybrid shredders combining electric and hydraulic drives.

Recycling-focused systems that ensure maximum recovery of materials with minimal environmental footprint.

Q1: What materials can a heavy duty industrial shredder process?

These machines can process plastics, metals, textiles, wood, organic waste, and municipal solid waste.

Q2: How do dual-shaft shredders differ from single-shaft shredders?

Dual-shaft shredders handle tougher, bulkier materials with higher torque, while single-shaft shredders produce more uniform output.

Q3: Are heavy duty shredders suitable for food waste?

Yes, they are widely used in food processing plants, hotels, and biogas facilities for shredding organic waste.

Q4: What industries benefit most from heavy duty shredders?

Industries such as waste management, recycling, manufacturing, hospitality, and municipalities benefit greatly.

Q5: How often should shredder blades be replaced?

Blade replacement depends on workload and material type. With carbide-tipped blades, replacement intervals are significantly extended.

Q6: Can shredders reduce compliance risks?

Yes, shredders ensure safe, compliant waste handling, helping businesses meet environmental regulations.

The heavy duty industrial shredder machine is more than just a waste processor—it is a strategic asset for businesses and municipalities aiming to improve efficiency, sustainability, and compliance. From reducing bulky waste to producing recyclable materials, these machines deliver unmatched performance across industries.

By selecting the right shredder, investing in durable components like carbide blades and ribbed roll rings, and adopting proper maintenance, businesses can maximize their return on investment while supporting a greener future. With innovations in automation, AI, and sustainable design, the role of shredders in modern industry will only continue to expand.

Phone: 0086-13816616775

E-mail: sales@fpdgreen.com

Address: 140 Jinjiabang Street, Tanghui Street, Xiuzhou District, Jiaxing City, Zhejiang, China