Kitchen waste is one of the most pressing environmental challenges faced by industries, municipalities, and households. Food scraps, peels, packaging residues, and organic matter contribute significantly to landfill waste, greenhouse gas emissions, and hygiene issues.

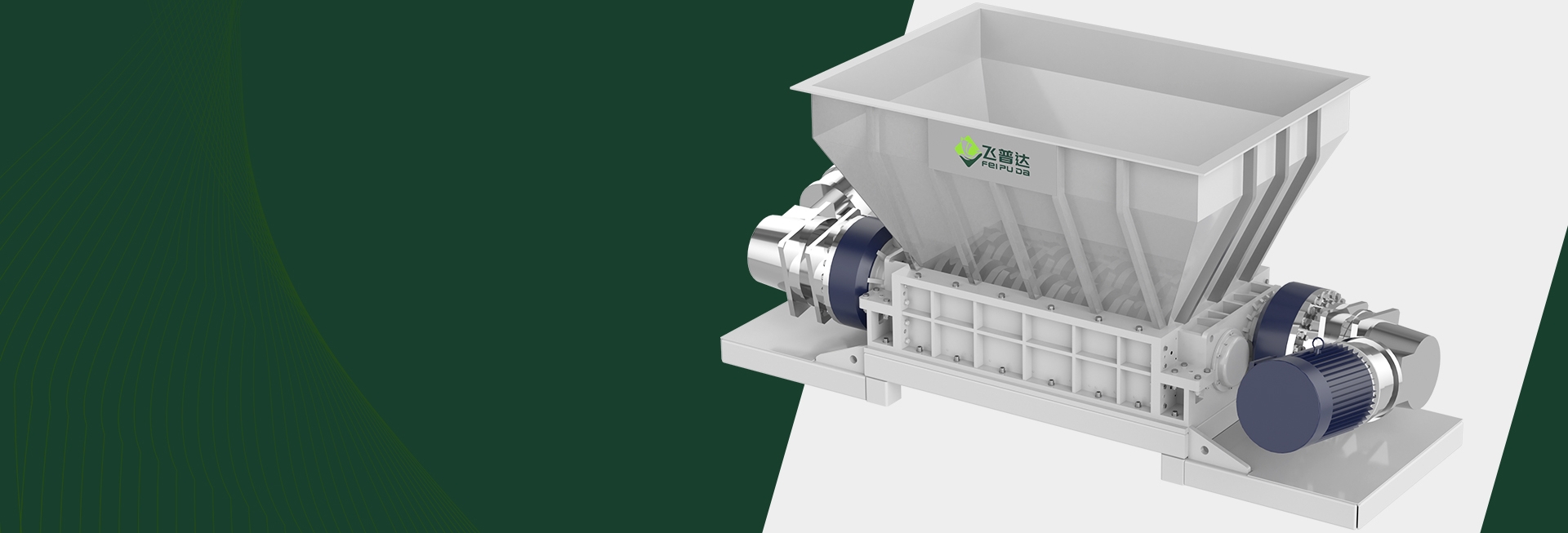

A kitchen waste crusher is an innovative machine designed to process and manage organic kitchen waste by grinding and crushing it into manageable particles. For industries and municipalities, investing in such technology not only improves sanitation but also aligns with global sustainability goals.

Across sectors, kitchen waste is increasing due to:

Urban population growth → higher food consumption.

Hospitality industry expansion → restaurants, hotels, and food courts generating tons of daily waste.

Industrial food processing → by-products, peelings, and organic remains.

Municipalities → handling mixed residential and commercial waste.

Unmanaged kitchen waste leads to foul odors, pest infestation, increased methane emissions, and unnecessary landfill burden.

A kitchen waste crusher operates through simple yet highly efficient steps:

Collection – Organic waste is gathered from kitchens or food processing units.

Grinding & Crushing – Waste is shredded into fine particles.

Dehydration – Liquids are separated from solids for easier disposal.

Output – The processed waste can be composted, recycled, or transported at reduced volume.

This process ensures cleaner kitchens, reduced transportation costs, and minimized environmental impact.

By reducing waste volume by up to 70–80%, crushers lower storage and transportation costs.

Crushers eliminate odors, reduce pest problems, and create safer environments for workers.

Processed kitchen waste can be composted, recycled, or converted into biogas, promoting a circular economy.

Governments require food businesses to adopt sustainable waste practices, and crushers help maintain compliance.

With faster processing, businesses spend less time and labor managing kitchen waste.

Hotels, restaurants, and canteens benefit from crushers by maintaining hygiene and reducing daily waste volumes.

Food manufacturing plants use crushers to manage organic by-products and maintain efficiency.

Large-scale waste crushers are installed in public waste collection facilities to handle urban food waste efficiently.

Green solution providers promote crushers as a vital step toward zero-waste goals.

| Feature | Kitchen Waste Crusher | Landfilling | Incineration |

|---|---|---|---|

| Volume Reduction | High | Low | Moderate |

| Hygiene | Excellent | Poor | Fair |

| Environmental Impact | Low | High | High |

| Cost Savings | Significant | Limited | High |

| Recycling Potential | Strong | None | Minimal |

Clearly, crushers are superior to conventional disposal methods, making them indispensable for modern waste management strategies.

When it comes to high-quality, durable, and eco-friendly crushers, FPD Green is a leader in the field. The company designs state-of-the-art waste crushers that serve industries, municipalities, and hospitality businesses worldwide.

Innovative Technology: Advanced crushing and dehydration features.

Industry Expertise: Proven track record in waste management solutions.

Custom Solutions: Crushers tailored to specific business needs.

Sustainability Commitment: Aligning products with green initiatives.

Comprehensive Support: Installation, training, and after-sales service.

FPD Green is not just a manufacturer but a partner in sustainable waste management.

Companies using kitchen waste crushers from FPD Green report:

Up to 50% cost reduction in waste handling and transportation.

Improved workplace sanitation.

Reduced environmental fines and regulatory risks.

Enhanced reputation as a green-conscious brand.

Looking ahead, kitchen waste crushers will integrate:

AI-based monitoring for smart waste tracking.

Automation for large-scale municipal projects.

Energy recovery systems to convert waste into renewable energy.

FPD Green continues to drive innovation, ensuring clients remain at the forefront of waste management technology.

Q1. What types of waste can a kitchen waste crusher handle?

It primarily handles organic waste such as food scraps, peels, and biodegradable materials.

Q2. Are crushers suitable for large-scale municipal use?

Yes, industrial-grade crushers can process high volumes of urban kitchen waste.

Q3. How do crushers improve hygiene?

By grinding and dehydrating waste, they reduce odor, pests, and bacterial growth.

Q4. Do kitchen waste crushers reduce costs?

Yes, they minimize transportation, storage, and disposal expenses.

Q5. Why choose FPD Green?

Because FPD Green offers customized, reliable, and sustainable crusher solutions with excellent after-sales support.

Q6. Can kitchen waste crushers help with zero-waste goals?

Absolutely. Processed waste can be composted or converted into renewable energy, supporting sustainability targets.

A kitchen waste crusher is more than just a machine—it’s a crucial step toward sustainable waste management. By reducing volume, improving hygiene, and enabling recycling, crushers help industries and municipalities meet both operational and environmental goals.

As a proven manufacturer and innovator, FPD Green offers advanced crusher solutions tailored to diverse needs. For businesses and municipalities committed to sustainability, FPD Green is the partner of choice in building a cleaner, greener future.

Phone: 0086-13816616775

E-mail: sales@fpdgreen.com

Address: 140 Jinjiabang Street, Tanghui Street, Xiuzhou District, Jiaxing City, Zhejiang, China