The global push for sustainable practices has made waste management a critical priority. With industries, municipalities, and commercial facilities generating massive amounts of waste daily, the role of an industrial waste extruder manufacturer has become more vital than ever.

An industrial waste extruder is a machine that compacts, dehydrates, and processes waste, drastically reducing volume and improving disposal efficiency. Choosing the right manufacturer ensures durability, compliance with regulations, and long-term cost savings.

Industrial waste continues to rise due to:

Expanding urban populations

Increased manufacturing and production

Growth of the food and hospitality industry

Stricter government regulations on waste disposal

For organizations in waste-heavy sectors, finding a reliable industrial waste extruder manufacturer is not just about technology—it’s about long-term sustainability and operational excellence.

Engineering Excellence – Precision design for durability and efficiency.

Customization Options – Machines built to handle organic, plastic, or mixed waste.

Regulatory Compliance – Technology that meets environmental standards.

After-Sales Service – Maintenance, spare parts, and technical support.

Sustainability Commitment – Eco-friendly designs aligned with global green goals.

Step 1: Shredding & Crushing – Bulky waste is broken down.

Step 2: Compaction – Waste volume is reduced.

Step 3: Extrusion & Dehydration – Liquids are separated, leaving dry waste.

Step 4: Output – Compact residue ready for recycling, transport, or energy recovery.

This efficient process allows organizations to cut down on landfill usage while lowering transportation and operational costs.

Machines designed by expert manufacturers can reduce waste volume by up to 80%, making storage and disposal easier.

Though initial investments may be significant, the ROI is high due to reduced labor, transportation, and landfill fees.

Moisture removal reduces odor, bacteria, and pests—critical for food and hospitality industries.

Top manufacturers design extruders that minimize power consumption and carbon emissions.

Manufacturers ensure equipment meets both local and international waste management regulations.

Restaurants and hotels use extruders to manage food scraps, packaging, and organic waste more hygienically.

Factories rely on extruders to process plastics, metals, and chemical residues safely.

Extruders are increasingly used in smart city waste projects to reduce landfill dependence.

Consultants and green solution providers recommend extruders as part of zero-waste initiatives.

| Criteria | Leading Manufacturer | Generic Supplier |

|---|---|---|

| Build Quality | High, durable, tested | Basic, often unreliable |

| Technology | Innovative, efficient | Outdated, standard |

| Compliance | Meets global standards | May lack certification |

| Customization | Tailored solutions | One-size-fits-all |

| After-Sales Service | Strong support & parts availability | Limited or none |

This comparison highlights why choosing a trusted manufacturer makes a long-term difference.

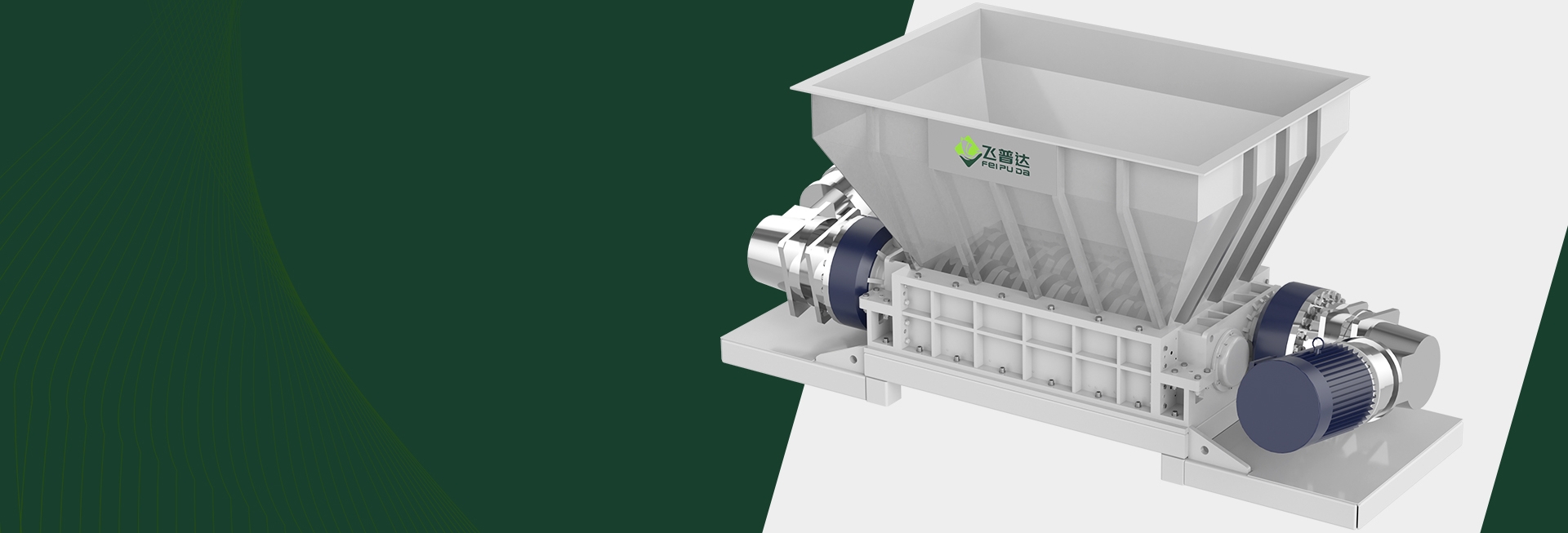

Among the leading names in the field, FPD Green stands out as a forward-thinking industrial waste extruder manufacturer.

Innovative Technology: Advanced design for maximum efficiency.

Proven Track Record: Trusted by industries, municipalities, and global partners.

Sustainability Commitment: Aligns with circular economy principles.

Tailored Solutions: Machines designed for specific industries.

Comprehensive Support: Installation, training, and ongoing maintenance.

FPD Green’s mission is clear: to provide high-performance, eco-friendly extruder technology that empowers organizations to achieve both profitability and sustainability.

Businesses investing in a reliable extruder manufacturer like FPD Green can expect:

Up to 50% cost reduction in waste handling.

Lower environmental compliance risks.

Extended equipment lifespan with professional support.

Improved brand reputation for adopting green practices.

The future will see manufacturers integrating:

AI and automation for waste sorting and monitoring.

Energy recovery features turning waste into usable fuel.

Global adoption as countries tighten waste regulations.

FPD Green continues to lead in next-gen waste management technology, positioning itself as a global sustainability partner.

Q1. What industries benefit most from industrial waste extruders?

Food, hospitality, manufacturing, and municipal waste sectors see the greatest advantages.

Q2. Why is manufacturer quality important?

A trusted manufacturer ensures long-lasting, compliant, and efficient machines.

Q3. How does FPD Green support clients after purchase?

Through installation, training, spare parts, and maintenance services.

Q4. Are industrial waste extruders customizable?

Yes, leading manufacturers like FPD Green design extruders tailored to specific waste streams.

Q5. Do extruders meet international waste management standards?

Yes, top manufacturers ensure compliance with strict regulations.

Q6. How do extruders save money long-term?

By reducing transportation, landfill, and operational costs while improving efficiency.

Choosing the right industrial waste extruder manufacturer is a strategic decision for any organization focused on sustainability, cost savings, and compliance.

With its proven expertise and advanced solutions, FPD Green stands out as a trusted partner for industries and municipalities worldwide. By investing in the right technology today, businesses not only manage waste better but also secure a greener, more sustainable future.

Phone: 0086-13816616775

E-mail: sales@fpdgreen.com

Address: 140 Jinjiabang Street, Tanghui Street, Xiuzhou District, Jiaxing City, Zhejiang, China